OUR PRODUCTS

STEEL

- REBAR: reinforcing steel in bars and in coils in accordance with many international product standards and with the quality certifications needed to operate in different countries.

- WIRE ROD: mesh grade low carbon, drawing quality medium carbon, and high carbon steel wire rods for many different sectors and applications.

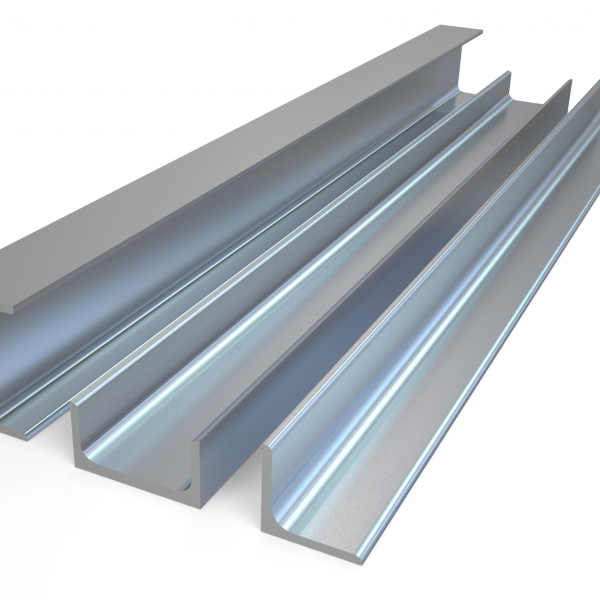

- MERCHANT BARS: Flat bars, round bars, T bars, angles, squares. Products offered in multiple qualities and dimensions.

- BEAMS: A wide range of structural sections including UPN, IPN, IPE, HEA, HEB, W-Beams and Channels.

- TUBES and PIPES: A broad portfolio of welded and seamless pipes in various shapes (round, square, and rectangular) and in different finishing processes.

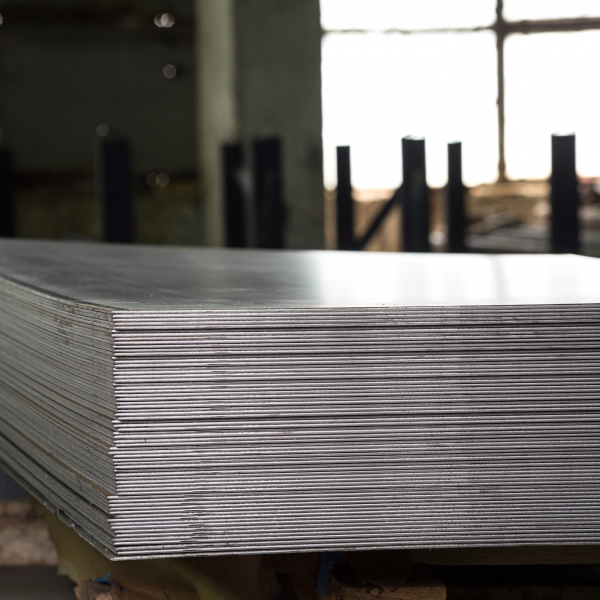

- HOT ROLLED: A wide range of Hot-Rolled Steel Coils (HRC) and Sheets (HRS), in different steel grades, typically used in many sectors including construction, automotive, heavy equipment and pipes.

- COLD ROLLED: Cold-Rolled Steel Coils (CRC) and Sheets (CRS) in numerous qualities, surface finishes, strengths, and chemistry.

- GALVANIZED: A variety of Galvanized (zinc coated) Steel Coils and Sheets with different coating thickness’ depending on the end use requirements.

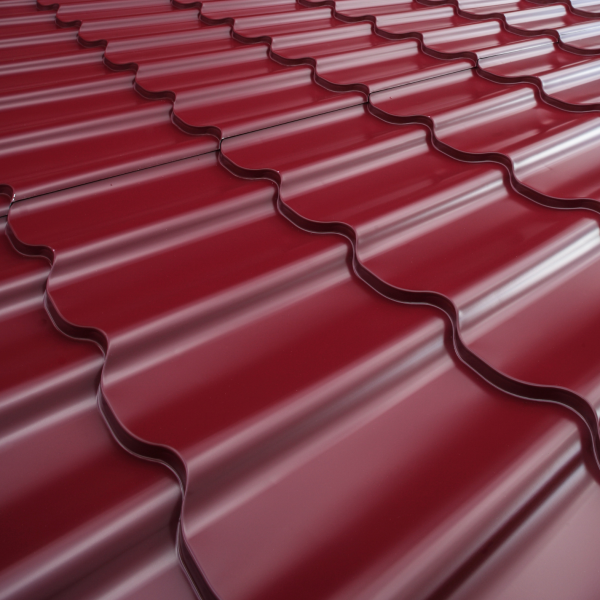

- PREPAINTED: A selection of Prepainted Steel Coils and Sheets typically used in many applications including metal roofing, garage doors, containers, and appliances.

A wide range of LONG and FLAT STAINLESS-STEEL PRODUCTS in different steel grades such as the 200 series Austenitic (chromium-manganese alloys), the 300 series Austenitic (chromium-nickel alloys) and the 400 series Ferritic (chromium alloys) and Martensitic (chromium alloys)

A wide selection of RING, SCREW, SMOOTH COIL and LOOSE NAILS, for pallet manufacturing, general construction applications and furniture fabrication. EPAL NAILS, for the production of EPAL certified pallets.

CEMENT

Our most common cements are:

- CEM I 42.5 N, CEM I 42.5 R and CEM I 52.5 N

- CEM I 42,5 N-SR5 and CEM I 42,5 R-SR5

- CEM II/B-LL 32,5 N, CEM II/A-LL 42,5 R

- WHITE CEMENT CEM II/A-L 42.5N

- CEMENT TYPES

- CEMENT 28-DAY STANDARD STRENGTH

- CEMENT EARLY STRENGTH

- CEMENT CONSTITUENTS

- CEMENT ADDITIONAL CHARACTERISTICS

- PORTLAND CEMENT, CEM I: Portland cement with at least 95% clinker.

- PORTLAND-COMPOSITE CEMENT, CEM II: Portland cement with additives such as fly ash, slag or limestone, up to a maximum additive content of 35%

- BLASTFURNACE SLAG CEMENT, CEM III: blast furnace and portland cement mixture in 3 classes: A, B and C; from lower to higher slag content (from 40% to 90%).

- CEMENTS CEM IV and CEM V: Blended cements produced by adding supplementary cementitious materials to portland cement clinker. CEM IV corresponds to Pozzolanic Cement and CEM V to Composite Cement.

The 3 classes of compressive strengths of the cement in megapascals (MPa) at 28 days are:

- Class 32.5: Low-strength cement typically used for non-structural applications.

- Class 42.5: Medium-strength cement typically used in general construction projects.

- Class 52.5: High-strength cement typically used in high-performance applications, such as precast concrete products, high-rise buildings, and bridges.

Two classes of early strength are included for each class of standard strength.

- N, Normal Strength: This is the most used cement in construction and it gains strength at a normal rate, making it suitable for general purposes.

- R, Rapid Hardening: This type of cement gains strength quickly and it is ideal for applications that require quick setting, such as precast concrete products, repairs, and emergency work.

There are further sub-classifications depending on the constituent’s content and type.

Content

- A: additive content <20%

- B: additive content 21 to 35%

Type

- V, W: Siliceous fly ash (V) and Calcareous fly ash (W)

- S: Granulated blastfurnace slag

- P, Q: Natural pozzolana (P) and Natural calcined pozzolana (Q)

- L, LL: limestone (LL: shall not exceed 0,20 % by mass and L: shall not exceed 0,50 % )

- T: Burnt oil shale

- D: Silica fume

- SULFATE RESISTANT PORTLAND CEMENT, SR: Typically used in sulphate rich environments to increase resistance against salt attacks. It is used for applications in sea and coastal structures, road works, irrigation, and sewerage.

- WHITE CEMENT: It is used in a wide range of esthetic and architectural applications.